Meet Protein Evolution: Biopure™️ biological recycling technology

Protein Evolution is a biological recycling company, meaning their technology engineers enzymes to transform textile and plastic waste into valuable matter which can be used to create new products. This technology reduces the industry’s reliance on fossil fuels through a biological recycling process that fuses enzymes with AI to break down polyester, alongside other synthetic fibres.

Producing plastic-based textiles uses an estimated 342 million barrels of oil every year, with polyester accounting for 80% of these synthetic fibres and plastic production resulting in over 1.6 billion tons of greenhouse-gas emissions annually. On top of this, 91% of plastic produced is not recycled, instead entering landfills, incinerators or missing the collection system altogether.

This year, Protein Evolution is partnering with Stella McCartney; applying their Biopure™️ technology to biologically recycle leftover fabric from our collections. We crafted the world’s first garments from this cutting-edge material, introduced at COP28. Protein Evolution is also supported by S🌍S Fund, a $200 million investment fund empowering the next generation of innovators, co-founded by Stella McCartney.

So, how does it work?

First, Protein Evolution selects the type of plastic waste they want to save from entering the environment – that could be a water bottle, car tire or piece of clothing. By fusing natural science with artificial intelligence, Protein Evolution develop specific enzymes formulated to combat each individual waste source.

What waste is produced?

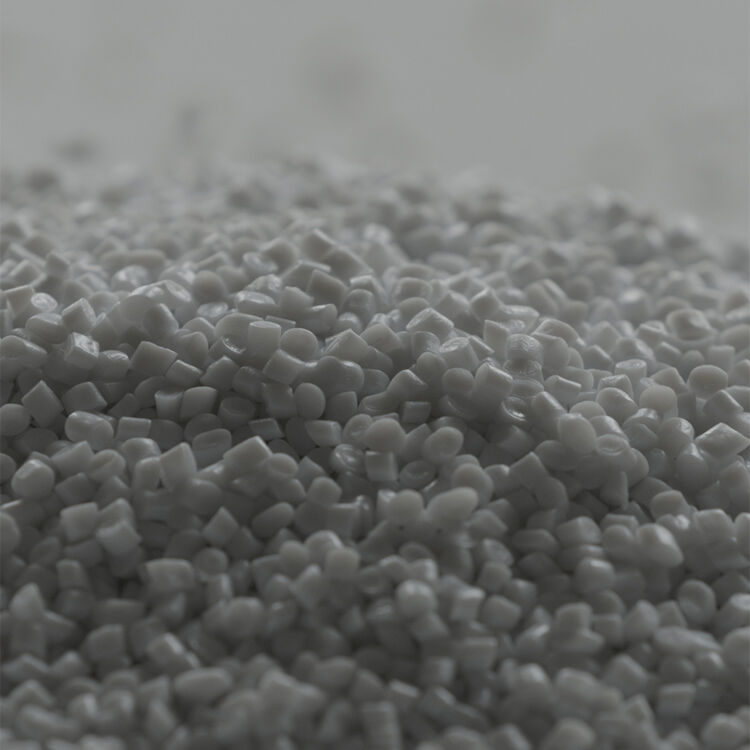

When the enzymes are combined with plastic waste, they break it down into what Protein Evolution call “building blocks” – these are blocks of plastic-based waste produced by a low-emission, eco-friendly process.

Is recycling a myth?

The UK produces more waste than it can process at home: around 230 million tonnes per year or 1.3kg per person, per day. As well as this, of the 8.3 billon tonnes of virgin plastic produced worldwide, only 9% has been recycled. So, it is not a myth.

How can we recycle or use the plastic waste created?

These “building blocks” can be used to create good-as-new plastic bottles, textiles, and other infinitely renewable plastic products. This year, Protein Evolution will apply their technology onto leftover polyester and nylon fabric from our collections. From there, we will work together to see how these new fibres can produce new clothing, footwear and more.

This exciting partnership takes scientific lab work into a real-world setting; a significant step towards integrating sustainable technology into existing manufacturing processes on a global scale. Basically, our collaboration will demonstrate to the world how complex fabrics, like nylon and polyester blends, can be totally re-used in a low-energy, cost-effective way.